LED,DIP,SMD,E-I-E-I-O

When it comes to LED lights, there are always a lot of different codes, like code, people who do not understand do not understand the mystery, people who understand will only feel very simple. Xiaobian I will explain the meaning of these terms in this article, I hope to help you plan LED lighting.

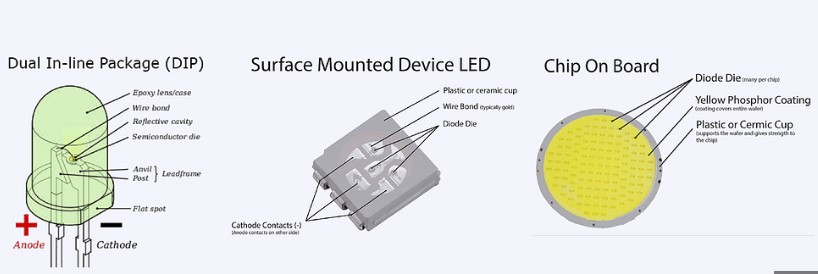

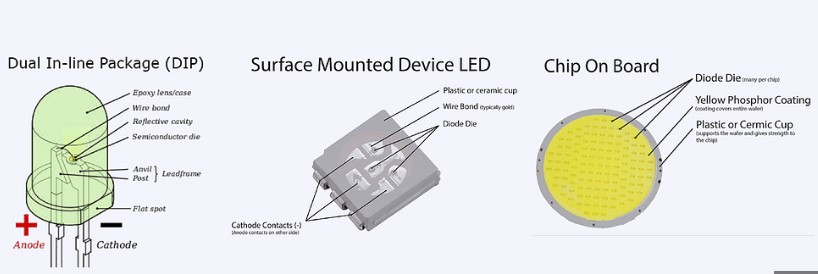

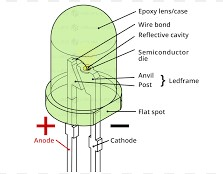

LED: short for light-emitting diode (Light Emitting Diode), DIP: short for double-line package (Dual In-Line Package), SMD: short for surface mounting device (Surface-Mount Device).

E-I-E-I-O:There is no special Chinese name, which is the abbreviation of English Emitter-In, Emitter-In, Emitter-Out, used to describe the encapsulation form and luminous angle of LED.

The above four encapsulation methods all have their own characteristics and application scenarios. For example, DIP package LED has better anti-interference ability and low cost, usually used for simpler applications, while SMD package LED has small volume, high brightness and good heat dissipation performance, suitable for various complex and high-performance applications.

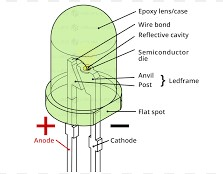

DIP packaging: In the 1970s, with the initial development of LED technology, the DIP packaging mode has already appeared. The DIP package LED has two pins, which is straight in. During the packaging process, the electrodes of the LED chip were first coated with silver glue, then the chip was mounted on the PCB or LED holder, and the welding was used to connect the chip to the PCB or bracket. The advantages of DIP packaging are simple structure, low cost and strong anti-interference ability; with the disadvantages including large volume and general heat dissipation performance.

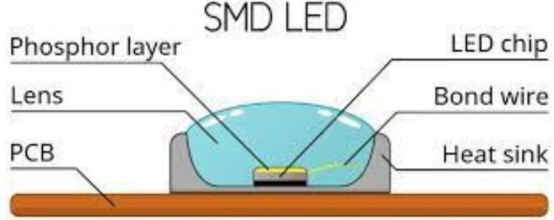

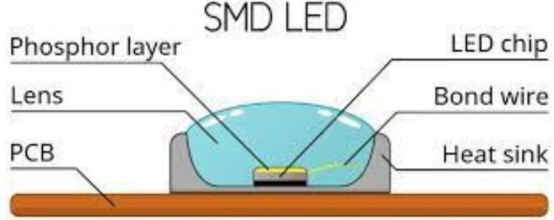

SMD packaging: In the 1990s, SMD packaging mode gradually emerged. The SMD package LED has a small volume, high brightness, and good heat dissipation performance. SMD packages can be divided into many types according to the number of chips and their color, such as three-in-one (RGB) and four-in-one (RGBA). During the packaging process, the electrodes of the LED chip are first coated with silver glue, then the chip is attached to the PCB, and the chip is connected to the PCB using welding. The advantages of SMD packaging are small size, high brightness and good heat dissipation performance; the disadvantage is relatively high cost.

COB packaging: In recent years, with the further development of LED technology and the improvement of application demand, the E-I-E-I-O packaging method came into being. E-I-E-I-O package is a new type of LED package, the LED chip is directly installed on the PCB board, with high brightness, good heat dissipation performance and long life. During the packaging process, the electrodes of the LED chip are first coated with silver glue, then the chip is mounted on the PCB plate, and the chip is connected to the PCB using welding. The advantages of E-I-E-I-O package are high brightness, good heat dissipation performance and long life; the disadvantage is high cost.

Surface mount components are basically what their names describe. Rather than the two pins running through the integrated board, this package is designed for the flat installation of the integrated board. This design innovation is necessary because as the components become smaller, engineers try to install more things on individual boards. These SMD LED provide more light than their predecessors, and are easier to install in the automated manufacturing process.

The DPI (Dots Per Inch) of an LED is a measure of image or display quality. It represents the number of pixels or dots that can be displayed or printed within one inch. In the field of electronic displays, the higher the DPI, the more delicate and clear the image on the display.

For LED display screens, the DPI value depends on the resolution and size of the screen. When determining the DPI value, the type of LED screen needs to be considered, such as P4, P6, etc., which represent the distance between two light points and are related to the image resolution. Generally, DPI values between 300 and 3600 are suitable for printing devices, while in electronic display devices, the PPI (Pixels Per Inch) unit is more commonly used.

The main differences between SMD LEDs and ordinary LEDs are:

1. Packaging method: SMD LEDs use surface-mount technology, while ordinary LEDs use traditional through-hole mounting.

2. Power size: SMD LEDs have a smaller power, while ordinary LEDs have a larger power.

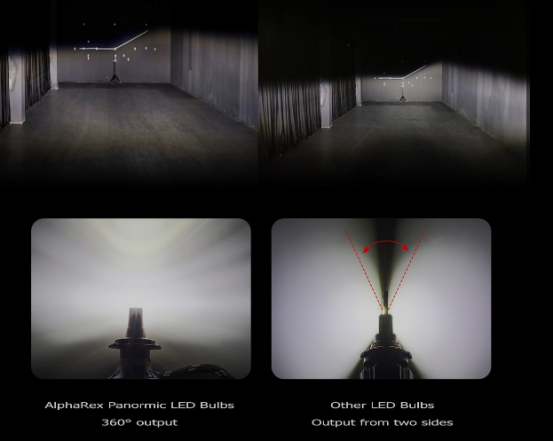

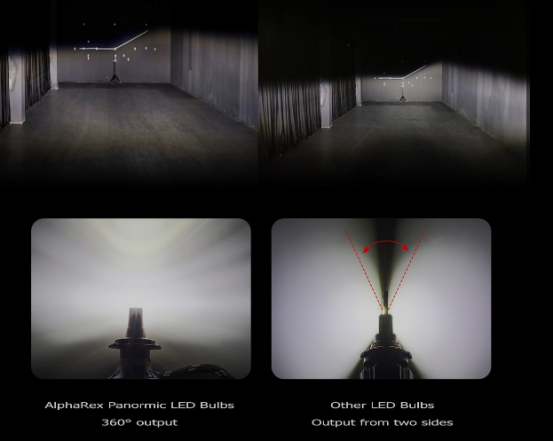

3. Illumination range: Ordinary LEDs have a smaller beam angle, more focused light; while SMD LEDs have a larger angle and more dispersed light.

4. Heat dissipation: Ordinary LEDs usually need to be used with a heat sink, while SMD LEDs rely on the heat dissipation performance of the circuit board itself.

5. Application scenarios: Ordinary LEDs are commonly used in lighting equipment such as streetlights, car lights, etc.; while SMD LEDs are mostly used in consumer electronic products such as LED displays, light strips, etc.

6. Cost-effectiveness: SMD LEDs have a relatively lower cost, while ordinary LEDs have a higher cost.

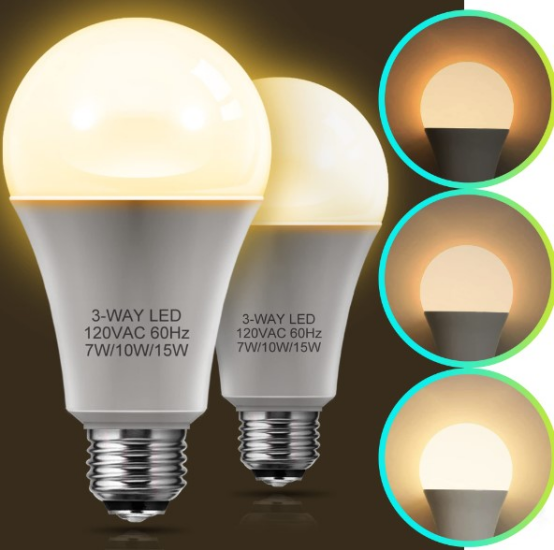

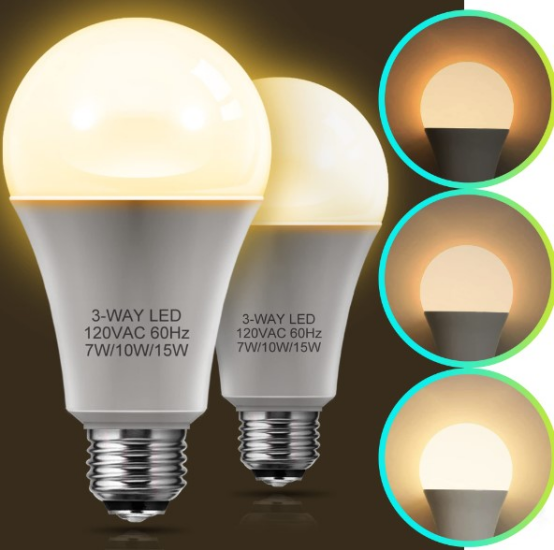

The main differences between LED bulbs and SMD bulbs:

1. Packaging method:

LED bulbs usually adopt ordinary LED packaging methods, while SMD bulbs use surface-mount technology (Surface-Mount Device, SMD) packaging. SMD-packaged LED bulbs are more suitable for automated production and high-density assembly.

2. Illumination range:

LED bulbs have a relatively smaller beam angle, more focused light, and are suitable for long-distance illumination. However, SMD bulbs have a larger angle and more dispersed light, making them suitable for area lighting.

Through the above content, we hope you can understand the information you need. We, TCWIN, welcome everyone to purchase and consult at any time!

![]() pkgled

LEDSMDBEADS

release time:2023-12-05 14:36:01

Reading volume:1

pkgled

LEDSMDBEADS

release time:2023-12-05 14:36:01

Reading volume:1