- Current Position : Magic color lamp beads > Blog > LEDSMDBEADS > text

different types of led strip lights

![]() pkgled

LEDSMDBEADS

release time:2023-12-14 11:16:23

Reading volume:1

pkgled

LEDSMDBEADS

release time:2023-12-14 11:16:23

Reading volume:1

What is an LED light bar?

An LED light bar represents a cutting-edge, multifunctional lighting solution. While there are various forms and exceptions, most LED light bars share the following core features:

- Constructed with numerous individual LED emitters arranged on a slender, flexible circuit board

- Operates using a low-voltage DC power supply

- Offers a range of fixed and variable colors and brightness levels

- Supplied in lengthy reels (typically 16 ft / 5 m), ready to be cut to desired lengths and equipped with double-sided tape for easy installation

Understanding LED light bar specifics

LED light bars generally measure half an inch (10-12 mm) in width and can extend up to 16 feet (5 m) or even longer. They can be easily trimmed to the desired length by cutting along pre-marked lines, usually occurring every 1-2 inches.

A single LED is positioned along the length of the light bar, with a typical density of 18-36 LEDs per foot (60-120 per meter). The color and quality of a single LED greatly influence the overall appearance and quality of the LED light bar.

The reverse side of the LED light bar features a pre-affixed double-sided tape, enabling users to simply remove the protective layer and attach the light bar to a wide variety of surfaces. Thanks to the flexible circuit board design, these light bars can even be mounted on curved or uneven surfaces.

Measuring LED light bar brightness

The brightness of an LED light bar is measured in metric lumens. Unlike traditional incandescent bulbs, different LED light bars can vary in efficiency, meaning the stated power rating may not always accurately reflect the actual light output.

The brightness of an LED light bar is commonly expressed in lumens per foot (or meter). A high-quality LED strip should offer at least 450 lumens per foot (1500 lumens per meter), which is comparable to the light output of traditional T8 fluorescent lamps. (For instance, a 4-foot T8 fluorescent lamp is equivalent to a 4-foot LED strip, which provides 1800 lumens.)

The brightness of an LED strip is influenced by three main factors:

- The optical output and efficiency of each LED emitter

- The number of LEDs per foot

- The power consumption per foot of the LED light strip

An LED strip lacking a lumen brightness specification should be considered a warning sign. Be cautious of low-cost LED strips claiming to have high brightness, as they may overdrive the LED, leading to premature failure.

LED density and power consumption

You may come across various LED emitter names, such as 2835, 3528, 5050, or 5730. However, these are not significant concerns when assessing an LED strip. The most crucial aspects to consider are the number of LEDs per foot and the power consumption per foot.

LED density determines the spacing between LEDs and the visibility of hotspots and dark spots between LED emitters. A higher density of 36 LEDs per foot (120 LEDs per meter) usually provides better and more evenly distributed illumination. The LED emitter is the most expensive component in the production of an LED strip, so consider the LED density difference when comparing prices.

Additionally, evaluate the power consumption per foot of the LED light strip. Power consumption helps determine the system's power usage, which is essential for calculating power costs and requirements (see below). A quality LED light strip should provide power of 4 watts or more (15 watts per meter) per foot.

Lastly, perform a quick check to determine if each LED is overloaded by dividing the wattage per foot by the LED density per foot. For LED light strip products, it is generally a positive sign if the driving power of each LED does not exceed 0.2 watts.

LED light with color options: fixed and variable colors

At times, you may desire a strong, vibrant color effect. Color LED light strips are ideal for achieving dramatic focus and lighting effects in such instances. They offer a wide range of colors across the visible spectrum, including purple, blue, green, amber, red, as well as ultraviolet or infrared light.

There are primarily two types of color LED light strips: fixed monochrome and color-changing. A fixed-color LED strip emits a single color and functions similarly to the white LED strips discussed earlier. A color-changing LED strip features multiple color channels on a single strip. The most basic type includes red, green, and blue channels (RGB), allowing you to mix various color components instantly and dynamically to create almost any color.

Input voltage and power supply

Most LED strips are designed to operate at 12V or 24V DC. When using a 120/240V AC standard mainsupply (e.g., a household wall outlet), convert the power supply to an appropriate low-voltage DC signal. This is the most common and simplest method with DC power supplies.

Ensure you have a sufficient power supply to power the LED lights (click here for detailed steps). Each DC power supply lists its maximum rated current (in amperes) or power (in watts). To determine the total power consumption of the LED strip, use the following formula:

Power = LED power (per foot) x LED strip length (feet)

For example, when connecting a 5-foot LED strip with a power consumption of 4 watts per foot:

Power = 4 watts per foot x 5 ft = 20 watts

The power consumption per foot (or meter) is typically listed in the LED strip's data sheet.

Connecting the LED light strip

Each LED strip must be connected to a DC power supply, or another LED strip connected to the DC power supply (daisy chain).

The connection method depends on the type of wire or plug attached to the LED strip and whether the DC power supply has a plug. If you are familiar with welding, this connection method can usually provide the most cost-effective and flexible solution. If you are unsure how to operate or do not want to deal with soldering, you can also use solder-free connector accessories to connect the LED strips to the power supply and other LED strips.

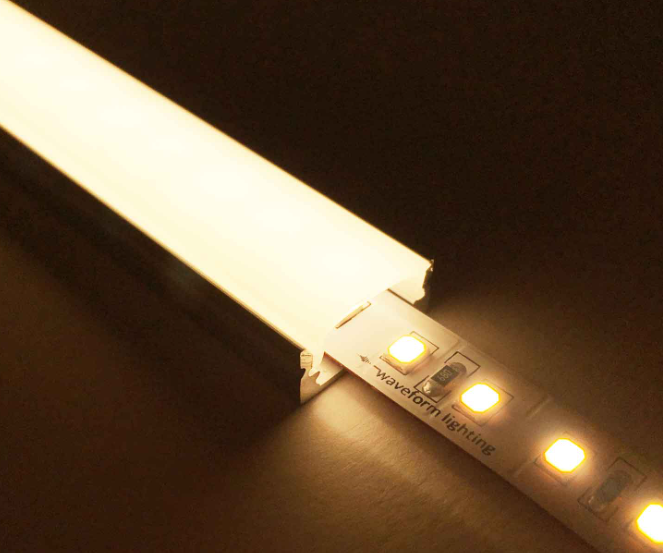

Aluminum tank and heat sink: Although the LED light strip is versatile and easy to use, it is still an exposed circuit board component. Installing the LED light strip in an aluminum channel and equipping it with a diffuser cover can significantly improve the aesthetics of the lighting device. Aluminum channels are usually U-shaped or V-shaped extruded aluminum. Place the LED light strips at the bottom of the channel and secure them with double-sided tape. Then, stick a piece of frosted polycarbonate plastic (usually provided with the aluminum channel) on top of the aluminum channel.

You may know that LEDs require effective thermal management to run reliably. High-quality LED strip products can actually reduce the driving force of the LED, and are designed to be sustainable for tens of thousands of hours without any heat dissipation. During operation, the LED light strip may feel hot, but the temperature rise is well below the thermal limit of the LED and circuit board components. (Our products usually increase by 55°F or 30°C above the ambient temperature without any heat dissipation.) Aluminum channels may help to dissipate heat from LED light strips, but in most cases, they are not necessary for thermal management and are mainly used for installation and diffusion purposes.

Dimming and color control: Unlike LED bulbs, all LED strips can be dimmed when paired with the correct device. There are two types of dimming methods for LED lights: traditional phase-cut wall dimmers or DC low-voltage dimmers. For residential and commercial lighting applications, the AC phase-cut dimming method is usually the most suitable, as the dimming input signals come from conventional wall switch dimmers. This setting requires a TRIAC dimming power supply.

The DC low-voltage dimmer or (RGB) controller commonly comes in the form of a manual or digital dimmer module, situated between the DC power supply and the LED light strip. This method is ideal for applications that require color changing or less permanent lighting fixtures.

How to Assess the Quality of LED Light Strips

At times, distinguishing between LED strips designed for high performance and longevity versus those that merely claim to be can be challenging. Here are some helpful tips to guide you:

Circuit board composition and quality - For higher-powered LED light strips, the quality and specifications of the underlying circuit board are crucial. With high currents flowing through each section, ample copper material is necessary. Look for LED light bars with at least 2 ounces of copper, preferably 4 ounces, to ensure the board can handle higher power – otherwise, you might experience voltage drops.

LED quantity and quality - The efficiency, quality, and stability of the optical output are directly determined by the LED emitter. Opt for LED light strips with strict quality control and specifications for LED emitters, and be wary of LED light strips claiming higher power despite a smaller number of LEDs, as this may indicate overdriving of the LED emitters, leading to premature failure.

LED strip surface - High-quality LED strips typically feature an additional white paint coating to help increase light reflectivity and boost overall light output. Lower-cost LED strip options omit this step, leaving the copper exposed. This can affect the brightness and color of the light, especially when installed in aluminum channels.

LED light bar material

The most prevalent type of LED light strips is the flexible substrate variety, available in 16-foot reels. The type of substrate used is commonly referred to as Flexible printed circuit technology (FPC). Flexible electronics have been around for some time and are invaluable in applications with tight or curved surfaces.

Flexible LED light strips make the most of this established technology and leverage the same underlying substrate characteristics. In most cases, they use polyimide (also known as PI) as the preferred material.

Polyimides are known for their remarkable durability and heat resistance while still maintaining flexibility. They play a crucial role in providing flexibility and structural integrity to LED lamp bars. The process begins with a copper layer, which serves as the base circuit. A core layer and two polyimide polymer outer layers, such as Kapton, are then applied to each side using a special flexible adhesive. This outer polyimide layer, often referred to as an "overlay," can be available in various colors. White is typically chosen to maximize reflectivity. These three layers of polyimides offer protection and structural integrity to the copper layer. However, in some small areas, the copper must remain exposed to allow LED and other components to establish electrical contact.

How long do LED light strips last?

On average, LED light strips have a lifespan of about 50,000 hours. However, this is just an average estimate. The impressive lifespan of an LED depends on its manufacturing quality and how it is used in your home. With proper maintenance, a strip lamp can be used continuously for approximately six years. For instance, when you're not using an LED light strip, always turn it off. This will prevent unnecessary power waste and extend its lifespan.

Did you know that LED is sensitive to temperature changes? Extreme hot or cold temperatures can significantly shorten their lifespan. It is recommended to keep the LED at a stable room temperature to maintain its longevity.

Unlike incandescent light bulbs, LEDs don't suddenly burn out and leave you in the dark. Instead, their brightness gradually decreases over time. Incandescent lamps shine through a filament, but the filament can suddenly oxidize and burn out. LEDs, on the other hand, experience "light decay," which means your lights dim significantly before they stop working.

The lighting industry measures the lifespan of LED light strips using the L70 indicator. This indicator determines how long it takes for the lights to start dimming. The L70 index is the light output decay point, also known as the time required for light production to be 30% less than its original luminescence. For example, our fully flexible FLEXile IP44 LED strip has an impressive bulb life of about 30,000 hours.

After three and a half years of constant use, your LED light strip will still produce 70% of its initial light output! The long lifespan of LED lights is one of their most appealing features. In addition, many people appreciate their energy efficiency.

Do LED light bars heat up?

LED strips do generate heat, but not like incandescent and fluorescent lights. About 90% of the energy used by incandescent bulbs is converted into heat. In fact, they produce so much heat that the bulb may shatter if left on for too long.

Due to the energy used to generate heat, incandescent bulbs are much less energy-efficient than LED lights. When an LED generates heat, it utilizes a "radiator" to release the heat into the surrounding air. This means the bulb can use 80% of its energy to produce light and 20% to dissipate heat.

Any object that uses electricity to generate light will also produce heat – that's a physical certainty! However, there's a reason why LED light strips have become one of the most popular lighting sources. Their incredibly high energy efficiency also makes them more cost-effective!

I hope this article will give you a deeper understanding of ---------. I am your editor from TCWIN, guiding you on the road to lighting.

Recommended content

TCWIN Awarded National-level Little Giants Enterprise Recognition

TCWIN obtained US8124988B2 magic lamp bead patent authorization

TCWIN Tiancheng - Brand Development History

Li Hao Rui: From 15-Year-Old Dropout to LED Industry Leader

Pick-up rhythm light rgb (brilliant light for the passionate stage)

different types of led strip lights

Surface mounting technology (SMT) panoramic analysis equipment, process and quality control

Comprehensive understanding of LED chips

recommended to you

TCWIN Awarded National-level Little Giants Enterprise Recognition

TCWIN obtained US8124988B2 magic lamp bead patent authorization

TCWIN Tiancheng - Brand Development History

Li Hao Rui: From 15-Year-Old Dropout to LED Industry Leader

Pick-up rhythm light rgb (brilliant light for the passionate stage)

different types of led strip lights

Surface mounting technology (SMT) panoramic analysis equipment, process and quality control