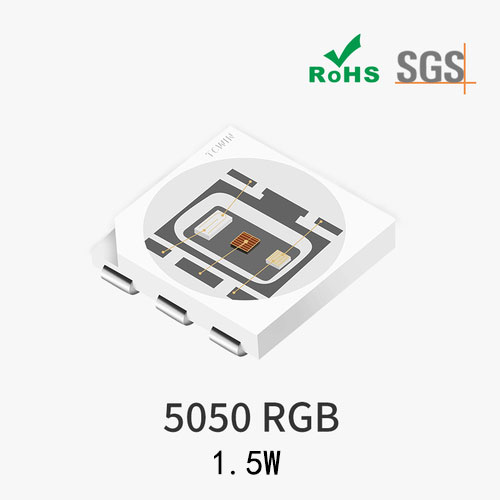

led smd 5050 rgb TX1813A

We supply led smd 5050 rgb TX1813A We devoted ourselves to lighting many years,coveringmost of Europe and the Americas market.We are expecting become your long team partner inChina.

- product brand: TCWIN

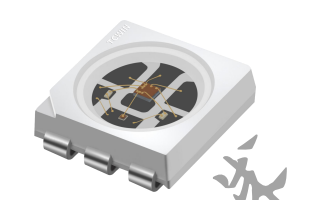

- Encapsulation: SMD

- Specification: 5050 rgb

- Product power: 0.2W

- Working current: 12ma

- Glowing color: Magic color

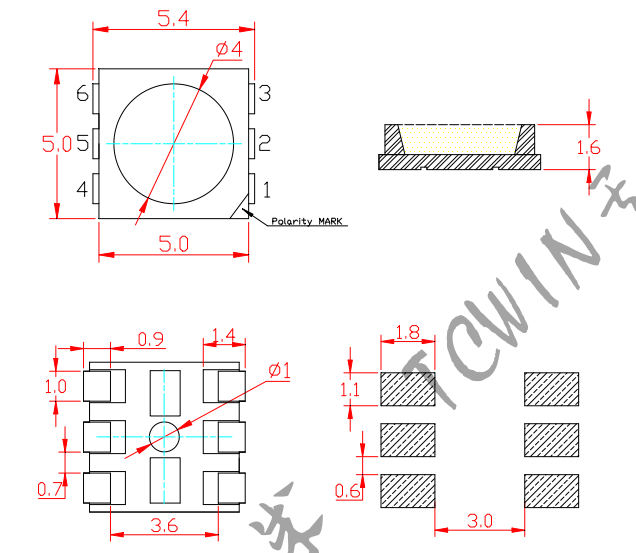

- Product Size: 5.0x5.0x1.6

- product name: led smd 5050 RGB Magic color

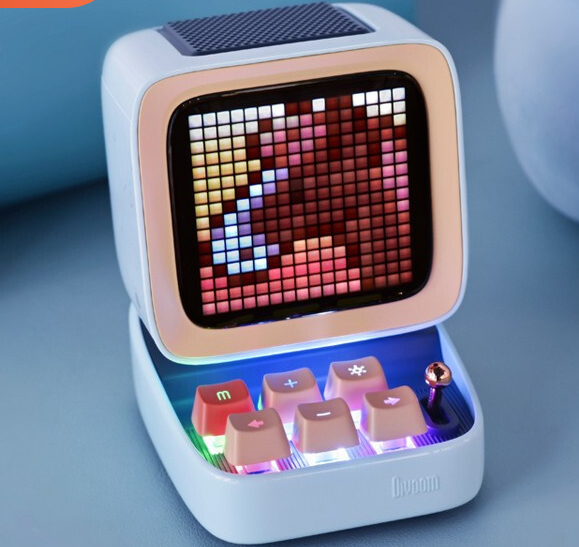

- Application field: (IC-embedded RGB strip series)LED RGB strip with integrated IC、Electronic products with built-in LED RGB strip lighting、Pixel screens with LED RGB strip lighting、Speakers with LED RGB lighting、Esports arenas with LED RGB lighting;The Internal IC series products are characterized by the integration of IC chips, which can realize single-point control and have higher flexibility and playability.

- Product Features: Self-contained packaging technology, good mixing consistency, high stability, and dead-light protection.

- Operating Voltage: 5V

Key Features

Low-voltage 5V power supply

Low-voltage 5V power supplies are safe and energy-efficient, making them suitable for a variety of applications, including home lighting, commercial lighting, and stage lighting. They are also widely used in LED strip lights, electronic products, pixel screens, speaker lighting, and esports lighting.

Features of low-voltage 5V power supplies

Safety: The low voltage of 5V makes it safer for humans and devices.

Energy efficiency: The power consumption of 5V voltage is relatively small, which can save electricity costs.

Wide applicability: The application range of 5V voltage is wide, which can meet the needs of various occasions.

Applications of low-voltage 5V power supplies

LED strip lights: LED strip lights are made of LED beads and can emit light in a variety of colors. 5V power supplies can provide safe and stable power for LED strip lights.

Electronic products: Many electronic products, such as computers, TVs, and smartphones, require low-voltage power supplies. 5V power supplies can provide safe and stable power for these electronic products.

Pixel screens: Pixel screens are made up of many small pixels and can display various images and text. 5V power supplies can provide safe and stable power for pixel screens.

Speaker lighting: Speaker lighting refers to installing LED strip lights on speakers to make speakers emit light in a variety of colors. 5V power supplies can provide safe and stable power for speaker lighting.

Esports lighting: Esports lighting refers to the use of LED strip lights in esports venues to create a cool atmosphere. 5V power supplies can provide safe and stable power for esports lighting.

Self-contained packaging technology means that the LED chip and control circuit are packaged together in a single unit. This has several advantages, including:

Improved reliability: The LED chip and control circuit are more protected from damage, which can lead to longer lifespan and lower maintenance costs.

Improved consistency: The light emitted from each LED is more consistent, which can lead to better color mixing and overall image quality.

Reduced cost: The self-contained packaging process can be more efficient than assembling the LED chip and control circuit separately, which can lead to lower costs.

Good mixing consistency means that the colors of the different LEDs blend together smoothly, creating a more uniform and appealing light output. This is important for applications where the color of the light is important, such as in mood lighting or decorative lighting.

High stability means that the LED is less likely to fail over time. This is important for applications where the LED is required to operate for a long period of time, such as in commercial lighting or signage.

Dead-light protection means that if one LED fails, the others will continue to operate normally. This is important for applications where the LED is required to provide a consistent light output, such as in emergency lighting or traffic signals.

Product Details

Appearance: Adopts a high-quality lens to ensure uniform light emission and excellent light efficiency.

Internal structure: Built-in IC control chip to realize single-point control and bad point continuity functions.

Product Certification

Advanced production equipment ensures product quality.

Strict production process ensures product consistency.

Quality materials ensure product durability.

Experienced technical team ensures product innovation.

Strong company strength guarantees product supply.

Multiple quality certifications ensure product safety.

After-sales Service

Nationwide warranty provides comprehensive after-sales service.

7-day no-reason return and exchange guarantees customer rights.

Professional technical support solves customer usage problems.

FAQ

Q: What is the power consumption of the product? A: The power consumption of 5V LED SMD 5050RGB 0.2W with built-in IC single-point control and bad point continuity is 0.2W.

Q: Is the color temperature adjustable? A: Yes, the color temperature of the product is adjustable, ranging from 2700K to 6500K.

Q: What is the lifespan of the product? A: The lifespan of the product can reach 50,000 hours.

Q: What is the price of the product? A: The price of the product is based on the quantity and batch, please consult customer service for details.

5V LED SMD 5050RGB 0.2W with built-in IC single-point control and bad point continuity is a product with multiple advantages, suitable for various lighting and creative display scenes, and has a high cost performance.

Customer Notice

Professional Internal IC LED Solution

Product Dehumidification

Due to the absorption of moisture by SMD products, water vapor will evaporate and expand during high-temperature welding, which can easily cause the chip and the gold wire connecting the holder to be pulled off. Therefore, customers should use 65-70 degrees to bake for more than 12 hours before use. After opening, the package should be welded in a short time and cannot exceed 24 hours. If it exceeds 24 hours, it needs to be dehumidified again. (Rolled baking: 65-75 degrees/10-15H Loose baking: 130-150 degrees/2-3 hours)

SMT Patch

When customers SMT patch, they should try to choose a suction cup larger than the light-emitting surface of SMD (gel), to prevent the damage to the internal gold wire of the LED caused by improper setting of the suction cup height. The suction cup height during SMT will also affect the quality of the LED, because the suction cup is too deep. Pressing the LED gel will cause the internal gold wire to deform or break, causing the fire bead to not light up or flicker, and quality problems. Selecting a suitable suction cup is the key to providing product process quality.

Hand soldering

It is recommended to use a constant temperature soldering iron and select a solder wire <0.5mm. The temperature should be controlled within 300 degrees. The welding time of a single LED should not exceed 3 seconds. During welding, the gel is in a high-temperature state. Do not press the surface of the gel, do not apply pressure to the LED pins, let the solder wire melt naturally and combine with the pins. Be careful not to use hard objects and objects with sharp edges to scrape, wipe, or press the surface of the gel, which can easily cause the internal gold wire to deform. Cause dead lights (batch production cannot be hand-soldered, because the quality of hand-soldered is not stable)

Reflow welding

During batch production, SMT patch production is required. It is recommended to use solder paste with a melting point below 220 degrees. It is best to use a reflow solder with eight temperature zones. The high temperature should not exceed 240 degrees and the peak time should be less than 10S. The reflow solder should be completed once. The LED cannot be reflow soldered more than twice. Multiple reflow soldering is destructive to the product. The LED should not be repaired after reflow soldering. When repair is inevitable, it must be operated by a heating plate or a skilled welder, but it must be confirmed in advance whether this method will or will not damage the LED itself.

Anti-static measures

During use, the machines that come into contact with the product need to be grounded with wires. The workbench should use a conductive table pad through a resistor to ground. The soldering iron on the workbench must be grounded. The operator must wear an anti-static ring, anti-static clothing, etc., and it is recommended to use a ion generator.

Product inspection

Please check the incoming materials carefully for the products shipped by our company. If there is any problem, please feedback in time. Before mass production, please first trial production in small batches to make sure there is no problem before mass production. The first picking should not exceed 10% of the total batch.

Recommended content

TCWIN Awarded National-level Little Giants Enterprise Recognition

TCWIN obtained US8124988B2 magic lamp bead patent authorization

TCWIN Tiancheng - Brand Development History

Li Hao Rui: From 15-Year-Old Dropout to LED Industry Leader

TCWIN Transparent Screen LEDs Shine at the 2023 Hangzhou Asian Games

recommended to you

TCWIN Awarded National-level Little Giants Enterprise Recognition

TCWIN obtained US8124988B2 magic lamp bead patent authorization

TCWIN Tiancheng - Brand Development History

Li Hao Rui: From 15-Year-Old Dropout to LED Industry Leader

Pick-up rhythm light rgb (brilliant light for the passionate stage)

different types of led strip lights

Surface mounting technology (SMT) panoramic analysis equipment, process and quality control

Comprehensive understanding of LED chips

Send Your Inquiry Today

related product recommendation

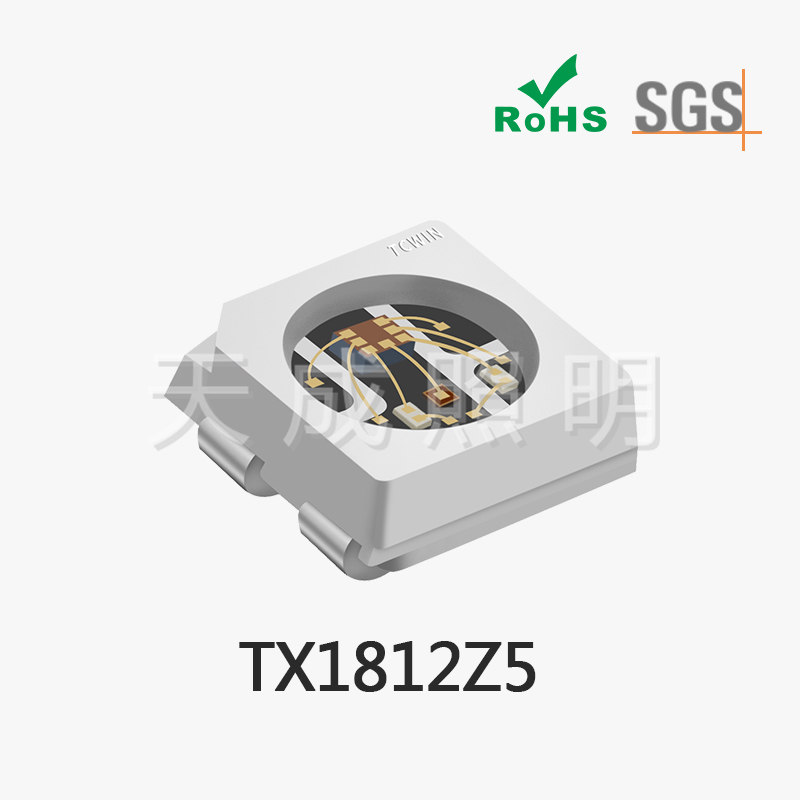

2020-TX1812Z5

Application Case DiagramProduct Dimensional DrawingparameterLow-current solution-2020 Fantasy LED be

Ceramics 3535UVC+A LED lamp beads

Ceramics 3535UVC+A LED lamp beads